Written by Ryan McGuine //

The modern age has been characterized by the skyrocketing use of a number of materials, including concrete, the most widely-used construction material in the world. It is so ubiquitous today that it is both hard to imagine a world without it, and easy to take it for granted. The basic foundation of concrete is cement, a remarkable material due to its combination of robustness and ability to be shaped into all manner of beautiful forms, and one which would seem futuristic if it weren’t thousands of years old. Going forward, rapid urbanization and rising incomes in developing countries will ensure the continued use of concrete for decades to come.

Concrete is made by a multi-step process. First, limestone, which contains calcium carbonate, along with clay, sand, iron ore, and bauxite is finely-ground and heated in a very high-temperature kiln to produce “clinker,” the key constituent of cement that gives it its binding properties. The main chemical reaction taking place during this step is “limestone calcination,” which transforms calcium carbonate (CaCO3) in the limestone to carbon dioxide gas (CO2) and solid calcium oxide (CaO). Next, the clinker is cooled, ground, and mixed with small amounts of gypsum and limestone to produce cement, which is typically packaged in standard unit quantities and transported. The cement is then combined with water and gravel in batch plants by ready-mix concrete companies. In compression, concrete can withstand 14,500 psi — about the equivalent of an elephant balanced on a coin — but can withstand less force per area than human skin in tension. Its tensile strength can be increased from 1,500 psi to around 3,000-5,000 psi by reinforcement with steel “rebar,” and while rebar eventually corrodes, leading to deterioration of the concrete, the strength advantages are so large that concrete is rarely poured today without reinforcement.

The earliest known use of limestone structures is the Göbekli Tepe site in modern-day Turkey, which dates back almost 12,000 years. Over millennia, numerous cultures made improvements to building materials, some of which may be seen as initial versions of concrete. For example, the ancient Egyptians may have cast blocks near the top of the pyramids using molds, and the Mayans used a form of cement quite extensively to build massive cities capable of withstanding harsh jungle conditions. However, the ancient Romans were the first to perfect the use of concrete, using it to create everything from mundane ramps and roads, to more elaborate structures like domes for temples and arches for aqueducts. Modern cement, commonly known as “Portland cement,” has many advantages over that used by the Romans, including higher strength and more precise mixtures, but Roman cement was actually superior in some applications — whereas seawater accelerates deterioration of concrete piers and harbors built using Portland cement, maritime concrete structures built by the Romans are stronger 2,000 years after being built thanks to exposure to seawater.

After the fall of the Roman Empire, concrete was largely forgotten about until the 18th century, when civil engineer John Smeaton used a limestone-clay conglomerate to construct a lighthouse in 1756 on the Eddystone Rocks, just off the southern coast of England. Sometime around 1824, bricklayer Joseph Aspdin patented a method of firing limestone and clay at high temperatures, and by the mid 1800s most industrialized countries were using something like modern Portland cement. However, without reinforcement, the possible applications were limited. French gardener Joseph Monier first discovered that the tensile strength of plant troughs made out of concrete could be increased by including steel bars during the 1860s, and François Hennebique, who was inspired by some of Mr Monier’s creations at the 1867 Paris Exposition, invented a system of using reinforced concrete in a range of other applications. Malleable enough to form unique structures like the Guggenheim Museum and the Sydney Opera House, yet durable enough to be used in massive dams and bridges, reinforced concrete was used with ever-more frequency throughout the Industrial Revolution and use skyrocketed in the early 20th century.

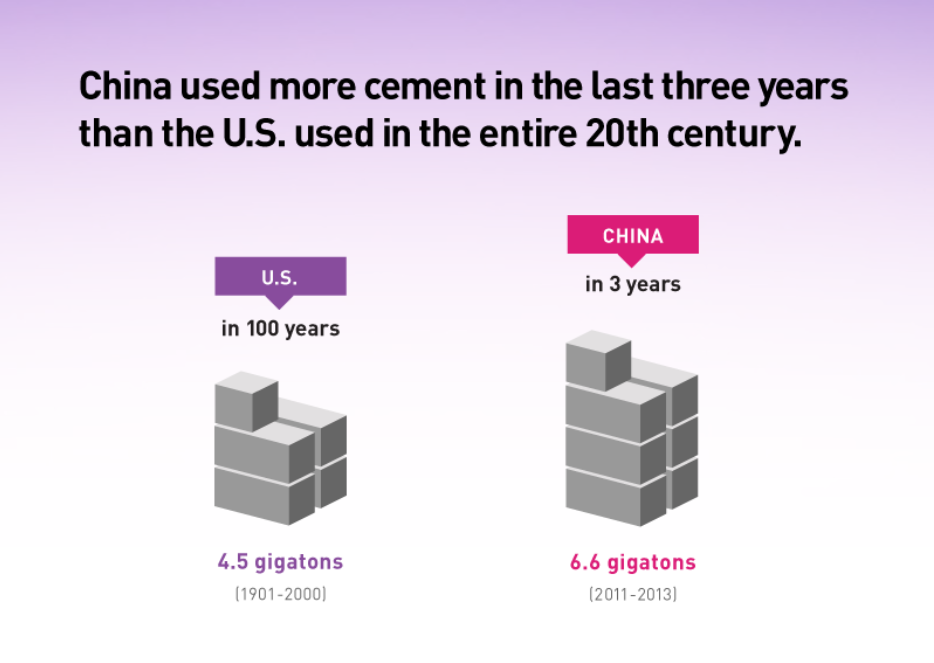

Today concrete can be found in all manner of structures, from hydroelectric dams to freeways to offshore drilling platforms to airport runways. America led the world in cement production for decades — annual usage increased ten fold between 1900 and 1928, peaked around 2005 at 128m tons, and has since leveled out to about 100m tons. China became the largest cement producer in 1985, and in 2017 alone poured 4.7 billion tons, more than the USA poured throughout the entire 20th century. Rapid urbanization around the world, most prominently in low- and middle-income countries, keeps demand high. For context, there were about 750m people worldwide living in cities in 1950. Today there are over 4 billion, and in order to accommodate all those urbanites, roughly eight New York Cities worth of concrete gets used annually.

Unfortunately, concrete production is associated with a number of environmental consequences. For example sand is one of the main constituents of concrete, and is mined by using dredging machines to scoop or suck sediment from waterways. Sand is a renewable resource to some extent, since it is created as waterways erode the landscape and deposit sediment, and most waterways can sustain some level of extraction. However, nearly twice as much sand is consumed today than a decade ago, and extraction exceeds the natural rate of deposit in many places. This results in coastline erosion, which diminishes beaches’ ability to absorb harsh weather, as well as changes to water quality, harming biodiversity. Regulation that keeps extraction rates in check would help, but sand mining is difficult to regulate because many of the rapidly-growing countries where demand is high, as well as many of those where large quantities of sand are mined, have low law enforcement capacity, creating a vibrant black market for the stuff — roughly three-fifths of extracted sand is traded illegally. Finding creative ways outside of concrete to reduce sand usage is also important. For example, coastal countries that wish to expand their territory can reduce sand use by draining those areas and using systems of dykes like is done in the Netherlands, rather than filling in the water with sand.

Additionally, as the footprint of cities continues to broaden, wetlands and other natural surfaces that absorb water are diminished. This can lead to increased flooding because stormwater management plans based on networks of impermeable surfaces only work if precipitation remains below average levels. Most of the time, precipitation makes its way to the earth and is absorbed, either via natural surfaces directly, or after running off impervious surfaces like concrete, asphalt, brick and stone to eventually reach a natural surface. However, when it rains exceptionally hard, or when stormwater management is poorly designed, flooding can become excessive. In order to prevent flooding, cities can increase permeable surface area by expanding green spaces, regeneration areas, and conservation areas, as well as by using new materials in place of standard concrete or asphalt. China’s “sponge cities” provide one example of how this might be done. Improvements that reduce water conveyance are also important. Even if more water is absorbed by permeable surfaces, there is still water rapidly moving from pipes and channels into larger central channels. The velocity of water toward those central channels can be reduced through methods that prevent moving water away from buildings, like adding vegetation, collecting stormwater in cisterns, and building local conveyance systems.

Finally, cement production is responsible for around 3% of global carbon emissions. Roughly 90% of concrete-related carbon emissions come from the production of Portland cement: 50% from limestone calcination, and 40% from the combustion of fossil fuels to heat the kiln. Thus, carbon emissions can be reduced first by minimizing the amount of clinker needed by recycling concrete, or using alternative sources of calcium carbonate like slag from blast furnaces and fly ash from coal-fired power stations. Emissions can also be reduced by alternative solutions to high-temperature heat from fossil fuel combustion, like hydrogen, biomass, or refuse combustion, as well as electrical heat. However, because demand for concrete will remain high for decades, and none of these solutions are able to completely eliminate carbon emissions, it is difficult to imagine how to achieve the reductions necessary without capturing carbon dioxide from exhaust streams at many cement production facilities. After being captured, it can be used productively or stored underground.

Going forward, using less Portland cement will probably be necessary, as will increasing energy efficiency. The former might be done by using alternative building materials like new cement formulations or wood. The latter might look like partnerships between industry and private research actors to accelerate technology development and adoption. Reducing the environmental footprint of concrete is a huge undertaking, but the harm caused by the status quo is significant. The problem is that it is currently free to pollute and expensive to be green, which creates incentives that lock in high-pollution outcomes. Environmental policies which reduce the cost of low-impact alternatives relative to high-impact technologies can help reverse that situation.